Dugovječnost kauča je određena njegovim skrivenim skeletom. Dok spona drži tkaninu, mehanička veza od šrafova i ugriza vijaka zavisi da li okvir traje godinu ili deset. U ovom vodiču detaljno su opisane posebne uloge Vratnice , T-matice , i Čelični vlakni u sprečavanju strukturnih kvarova.

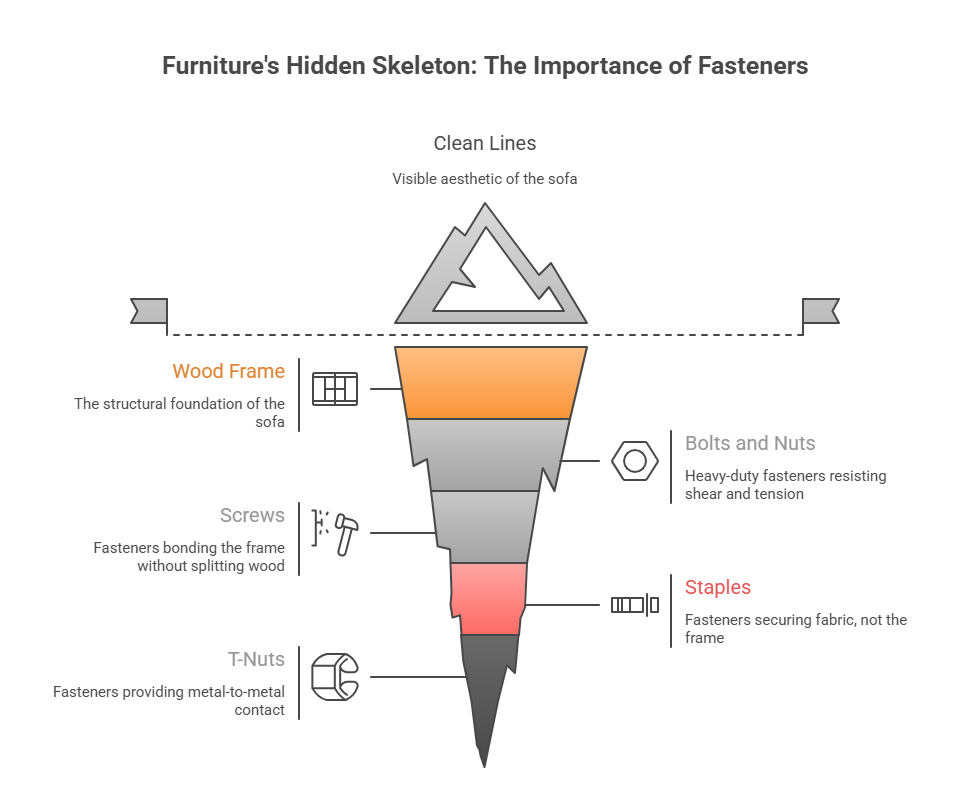

Pogledaj kauč. Ima čiste linije. Ima mekanu kožu. Ali unutra, postoji kostur. Skriveno je.

Ovaj kostur odlučuje da li namještaj traje 10 ili 1 godinu. Drvo je kost. Spojnice su spojevi.

Pogledavamo metalne dijelove koji drže drvo zajedno.

-

-Bolti i orahe. Oni rade teške poslove. Oni zaustavljaju šišanje i napetost.

-

-Vraće. Ugrizu u drvo. Oni vežu okvir bez razdvajanja zrna.

-

Zavojci. Oni povlače kožu čvrsto. Oni su za tkaninu, ne okvir.

-

-T-Nuts. Stavljaju metal protiv metala. Oni štede drvo kada pomakneš noge.

Ne gledaj samo na površinu. Pogledaj što ga drži.

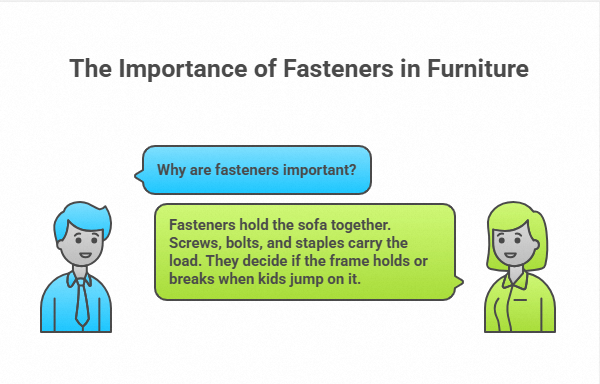

Zašto su čvrstici važni?

Problem je: Kupite lijepi sopstveni kauč. Izgleda savršeno u izložbi. Ali nakon šest mjeseci, naslon za ruke počinje se okretati. Godinu dana kasnije, vrišti svaki put kad sjedneš.

Agitacija: Nema ništa gore od ulaganja u "kvalitetne" namještaja koji se nakon minimalne upotrebe osjećaju jeftino i nestabilno. Uništava ti odmor i košta ga popraviti ili zamijeniti.

Rješenje: Razlika između kauča koji traje deset godina i jednog koji traje godinu dana obično nije tkanina ili drvo - to su vezivači.

Spojnice drže kauč zajedno. Žicu, vijke i spone nose teret. Oni odlučuju da li će okvir držati ili slomiti kad djeca skoče. -Ne, ne, ne.

S druge strane, za uređaje za proizvodnju električnih vozila

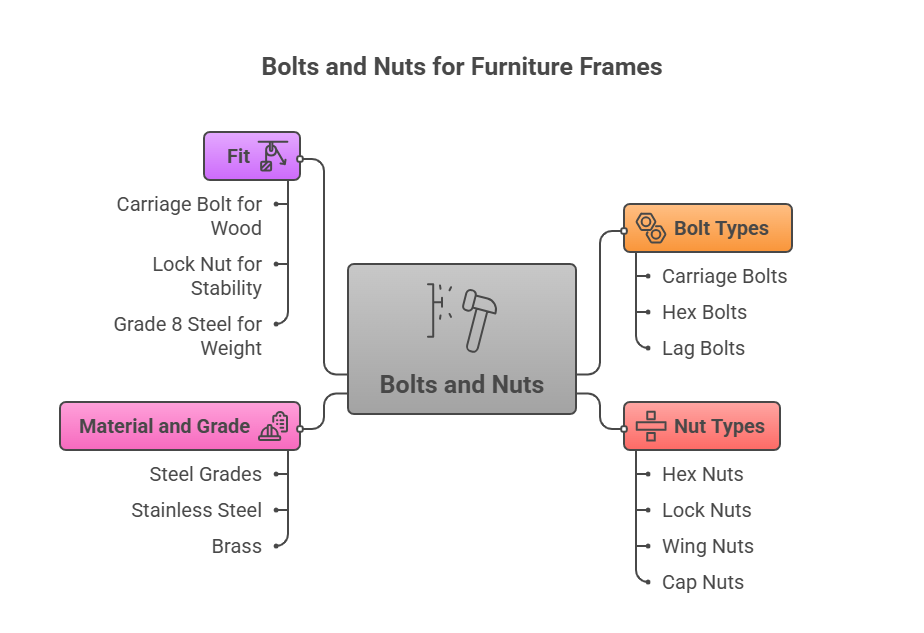

Boltovi su najjači spojevi. Ne grizu u drvo kao vijci. Prolaze kroz njega. Luđak ih zaključava na mjestu. Ovo je mehanička veza. Ne ovisi o drvenom zrnu.

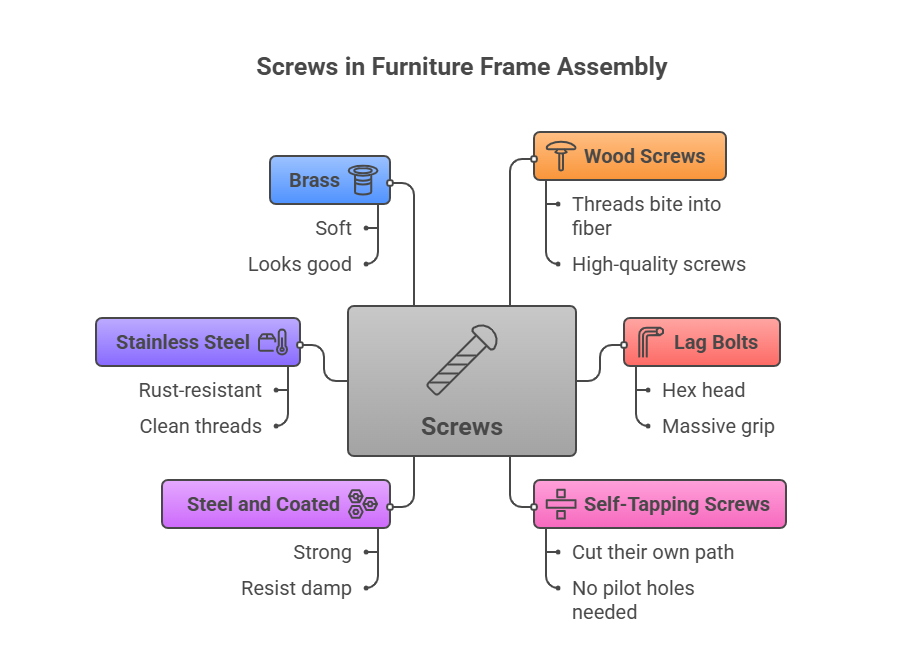

Nisu svi vijci isti. Dizajn je važan.

-

Za uporabu u proizvodnji električnih vozila Glava je glatka kupola. Ispod glave je četvrtasta šaka. Štap ugrize u drvo. To zaustavlja vijak od rotiranja kada ste zategnuti maticu. To je neophodno za drvene okvire.

-

Sklopci za šesterostruke vijke: Glava je šestostrana. Vozi se ključem. Koristite ovo za veza s visokim obrtnim momentom. Oni se spajaju s teškim metalnim tračnicama ili debelom drvenom pločom.

-

Lag bolti: Ovo su teške vijke s vještičjom glavom. Oni vežu drvo za drvo gdje ne možete doći do druge strane.

Bolt drži težinu. Luđak ga drži tamo.

-

Sljedeći proizvodi: Standardni izbor. Šest strana. Dobro za opće skupštine.

-

Smanjenje i smanjenje emisije: Vibracije ubijaju namještaj. Selidba stvara praznine. U matici je najlon prsten. Zgrabi se za nit. To zaustavlja budala od povlačenja. Nema opuštanja. Nema vrištanja.

-

Krilske orašastice: Imaju dva krila. -Tegneš ih ručno. Koristite ih za noge koje često morate ukloniti.

-

Sljedeći proizvodi: Vrh je kupola. Pokriva oštru nit. To štiti tkaninu i daje završen izgled.

Snaga dolazi iz metala.

-

Sredstva za proizvodnju: Razred 2 je standard. Pet i osam su teži. Teški namještaj treba veću kvalitetu kako bi se metal ne širio.

-

Nerustingajući čelik: Otporan na hrđu. Ako živite blizu oceana ili u vlažnom području, koristite nerđajući. Rasta jede nit. Nehrđajući ga čuva čist.

-

Brass: Meka je, ali dobro izgleda. Koristi ga za razotkrivene detalje.

Pripremi spojnicu za teret. Vlakni štap zaključava drvo. Uštrica zaustavlja ljuljanje. Čelični razred 8 podnosi težinu. Ne nagađaj. Koristi pravu opremu.

S druge konstrukcije

Boltovi mogu nositi teška tereta. Žicu daje oblik. Oni se spajaju s unutarnjim drvenim blokovima i šinama. Oni zaključavaju geometriju kauča.

Žicu treba držati bez uništavanja drveta.

-

S druge strane, za proizvodnju električnih vozila: Dizajniran za drvo. Vlaci ugrize vlakno. Visokokvalitetni vijci ne razdvajaju drvo. Razdvojena šina je propali okvir.

-

Lag bolti: Ovo su teške vijke s vještičjom glavom. Koristite ih za debele veze drva na drvo gdje orah ne može doći. Oni pružaju masivan prijem.

-

S druge strane, za vozila s brzinom manjom od 50 km/h: Najbolje za MDF ili mekano drvo. Oni su sami sebi otvorili put. Nema potrebe za pilotnim rupama. Napad je trenutni.

Jeftini metal hrđa. Rasta razbija vezu.

-

Slastični i premazani: Standard za unutarnju strukturu. Oni su jaki. Odupiru se vlažnosti.

-

Nerustingajući čelik: Odbitna za vlažne klime. Rasta jede niti. Nehrđajući ih čuva čiste.

-

Brass: Mekan je. Izgleda dobro. Koristite ga za razotkrivene detalje, nikad za glavnu strukturu.

Jeftini vijak se opusti. Kvalitetni vijak ostaje na mjestu. Okvir ostaje krut.

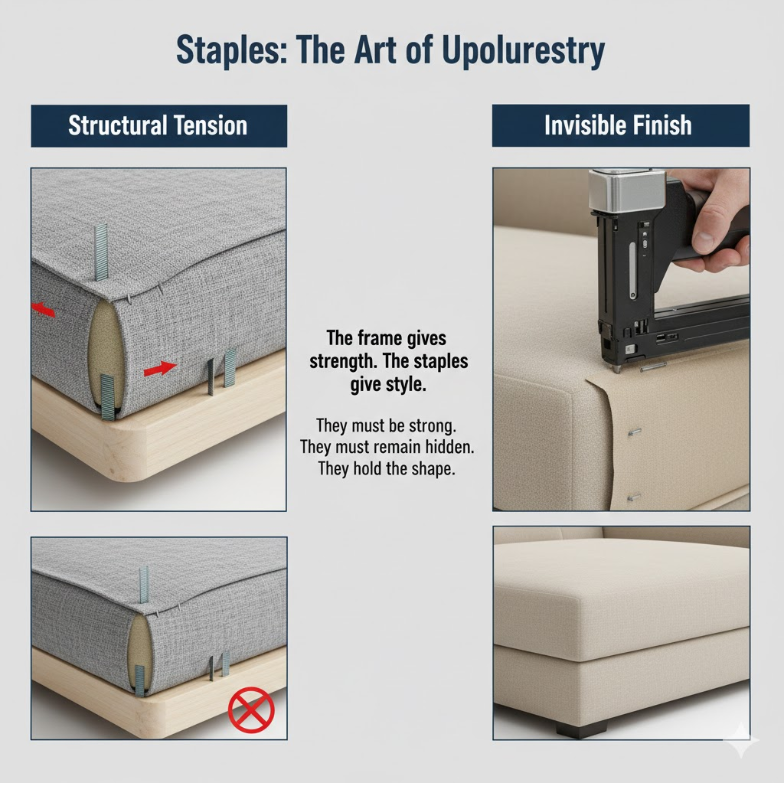

Sklopice: umjetnost tapeta

U svijetu namještaja, spona su industrijske klase. Oni su glavno vezivo za "kožu" kauča.

Složke imaju dvije glavne funkcije u tapetaži:

Stručna napetost: Oni stisnu tkaninu, kožu ili mrežu na okvir. Ako se ne uspiju spojiti, tkanina se spusti i nabori.

Nevidljivo završetak: Slagalice omogućuju tapeteeru da veže tkaninu u skrivena područja (kao što su pod naslonima za ruke ili stražnji panel) kako bi stvorio bezšiv, čist izgled.

Okvir daje snagu. Zapice daju stil. Moraju biti jaki. Oni moraju ostati skriveni. Drže oblik.

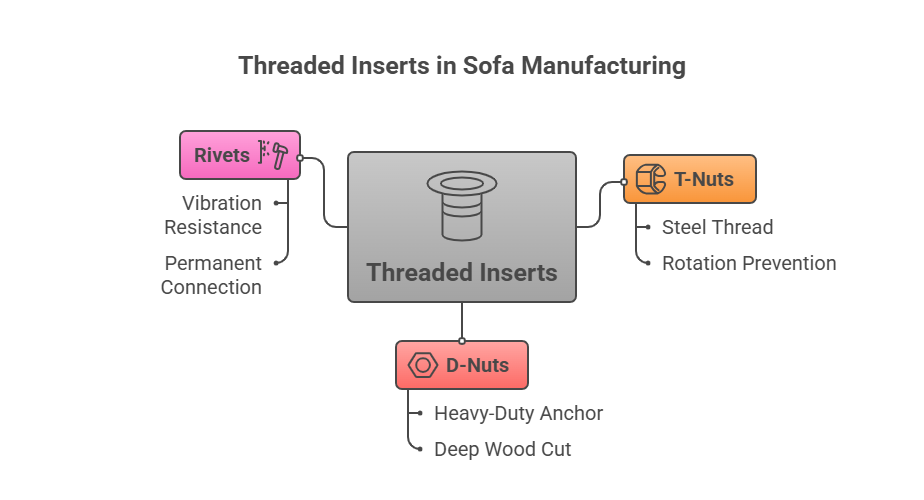

S druge strane, za proizvodnju električnih vozila

Drvo je mekano. Metal je tvrdoglav. Ako metalu staviš metalu u drvo, vlakna se razbijaju. -Ruka postaje velika. Noge padaju.

Da bi se to riješilo, proizvođači koriste umetke. Stvaraju trajni metalni utičnik unutar drvenog okvira. To omogućuje spojni sustav .

-

Sljedeći proizvodi: Ubiješ ih u drvo. Kosti ugrize drvo da zaustave rotaciju. Oni pružaju čeličnu nit za vijke i noge.

-

D-Odeljak (Umetni Odeljak): Zaviješ ih pomoću čarobnog ključa. Duboko su se isjekli u drvo. Oni nude tešku usidrenost.

-

Zakovicе: Koristi se za metalni okvir nameštaja. One su trajne. Vise su od vijaka. Ne puštaju se.

Sofi moraju proći kroz vrata. Noge često moraju biti odsječene. Uz T-Oštar i D-Oštar, možete sastaviti i rastaviti namještaj mnogo puta. Šraf ide u metalnu ulaznicu, a ne u drvo. Okvir ostaje netaknut. Veza ostaje čvrsta.

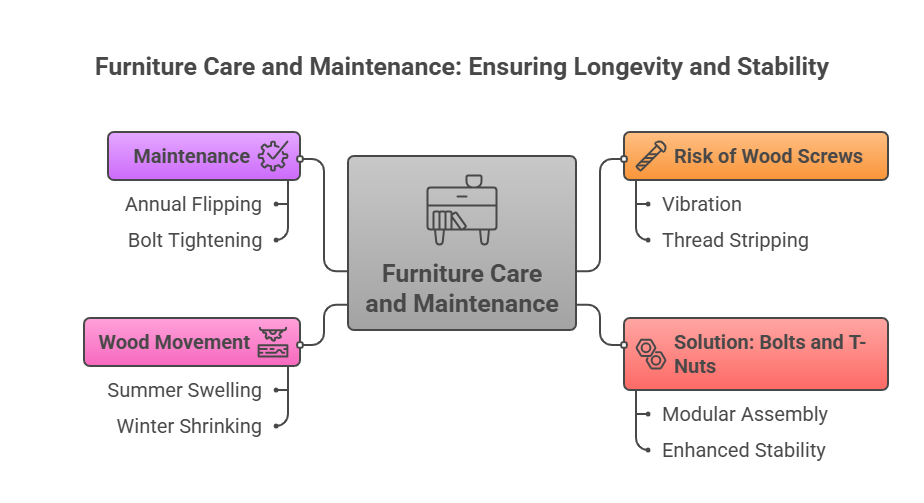

Održavanje namještaja

Seliš se. Kamion vibrira. Stepenice su uske.

-

Rizici: Sofa povezana samo drvenim vijcima pati. Vibracija otpušta vijak. Drvena nitka se povlači. Zajednica ne radi.

-

Rješenje: Kupite namještaj s S druge strane, neovisno o tome jesu li to proizvodi ili nisu, - Što? Skini noge. -Pokrij okvir. Dođite u novi dom. Spojite ga. -Tvrdo je kao i prvi dan.

-

Zvuci: Wood je živ. Otpuha u ljeto. Smanjuje se zimi. Ovaj pokret oslobađa vezu. Čvrstak nije nedostatak. To je signal.

-

Rješenje: Jednom godišnje, okrenite kauč. Provjerite glavne vijke na nogama. Okrenite se. Prestani kad bude čvrsto. Tišina se vraća.

Često se javljaju pitanja: Činjenice o vezivačima

P: Zašto neke kauče koriste spone za okvir? U jeftinijim namještajima, industrijske spone se ponekad koriste za stolariju okvira. Međutim, kvalitetni namještaj na naručje treba se oslanjati na štapove, vijke i vijke za okvir, a ne na čepove za vezanje tkanine i mreža.

P: Jesu li nevidljivi čvrstiji? A: "Nevidljivo" obično se odnosi na postavljanje. Skrivene vezice stvaraju minimalistički, elegantni izgled. Odlični su za dizajn visoke klase, ali za njih je potrebna veštačka vještina. Oni nude istu snagu, ali s boljim estetskim završetkom.

P: Što ako se vijak iskopce iz drveta? O: To se događa ako je pogrešno zavijanje korišteno ili prezažnjeno. Često se može fiksirati pomoću malo većeg vijka ili ugradnjom navojne uložke (D-Nut) kako bi se osigurao sveži prijem.

Tražite kvalitetu?

Ne gledaj samo tkaninu. Pitaj o izgradnji. Da li ste dizajner koji traži S druge strane, za proizvodnju proizvoda iz poglavlja 9 ili vlasnik kuće traži dugovječnost, snaga je u detaljima.

Izvor: Izvor:

- Svaka vrsta proizvoda Najjače vezivače za podizanje teških stvari. Mehaničke vezive koje ne oslanjaju na zrno.

- Svaka od sljedećih vrsta: Četvrto šipka ugrizne u drvo kako bi se spriječilo prevrtanje; neophodno za okvire.

- - Ne, ne, ne, ne, ne. Najlonski vložci sprečavaju otpuštanje uzrokovano vibracijama.

- Kvaliteta čelika: Za teške namještajne proizvode koristite razinu 5 ili 8 kako biste spriječili šišanje.

- -T-Nuts: Stvaranje trajnog uglaca između metala, koji sprečava oduzimanje drveta tijekom kretanja.

- Lag bolti: Čvrste vijke s šesterostrukim glavama za debele veze drva s drvetom.

- Spojnice: S obzirom na to da je to primjenjivo za proizvodnju materijala od čelika, to se primjenjuje samo na proizvodnju čelika od čelika. ne za stolariju okvira.

- Funkcija: Pruža "Nevidljivi završetak" i vuče kožu čvrsto.

Izvor: In-Depth: Različite uloge štapova, vijaka i vijaka u proizvodnji kauča